The Art of Crafting Handmade Moroccan Tiles: From Clay to Zellige

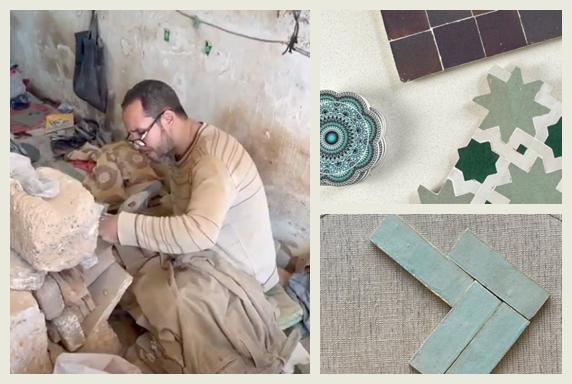

Handmade Moroccan tiles, known as Zellige, are renowned for their vibrant colours and intricate patterns. The creation of these exquisite tiles is a time-honoured tradition, meticulously followed by skilled artisans in the historic region of Fes, Morocco. Here’s a glimpse into the detailed process of how these beautiful tiles are crafted, from sourcing the clay to producing the final product.

Sourcing the Clay

The journey of a Zellige tile begins with the sourcing of natural clay from the rich deposits around Fes. This specific clay is chosen for its exceptional quality and workability. The clay is carefully extracted, ensuring minimal impact on the environment, and transported to the artisans’ workshops.

Preparation of the Clay

Purification:

The raw clay is first purified to remove any impurities. This involves washing and sieving the clay to achieve a smooth and consistent texture.

Kneading:

The purified clay is then kneaded by hand or with the help of machines to attain the right consistency. This process ensures that the clay is pliable and free of air bubbles.

Shaping the Tiles

Forming:

The kneaded clay is rolled out into flat slabs of the desired thickness. Using wooden molds or freehand techniques, the artisans cut the slabs into specific shapes, ranging from simple squares to intricate geometric patterns.

Drying:

The shaped tiles are left to dry in the sun for several days. This slow drying process helps to prevent cracking and ensures the tiles retain their shape.

Firing the Tiles

First Firing (Biscuit Firing):

Once the tiles are thoroughly dried, they are placed in traditional kilns and fired at high temperatures. This initial firing, known as biscuit firing, hardens the tiles and prepares them for glazing.

Glazing the Tiles

Preparation of Glaze:

The glaze, made from a mixture of ground glass, minerals, and natural pigments, is carefully prepared. The artisans use traditional recipes, often passed down through generations, to achieve the vibrant colors characteristic of Zellige tiles.

Application of Glaze:

Each tile is individually glazed by hand. The artisans either dip the tiles into the glaze or apply it with brushes, ensuring an even and smooth coat.

Second Firing (Glaze Firing)

Glaze Firing:

The glazed tiles are placed back in the kilns for a second firing. This step fuses the glaze to the tile surface, creating a durable and lustrous finish. The high temperatures also enhance the vivid colors of the glaze.

Final Touches

Quality Control:

After the glaze firing, each tile undergoes a thorough quality check. The artisans inspect the tiles for any imperfections and ensure that the colors and patterns meet their high standards.

Polishing and Finishing:

The edges of the tiles are often polished to ensure smoothness. Any excess glaze is carefully removed, and the tiles are cleaned and prepared for packaging.

Bringing Zellige to Your Home

The finished Zellige tiles, each a testament to the artisan’s skill and dedication, are then carefully packaged for shipment. We at Zellaus personally import these tiles from Fes, ensuring that each piece retains its authenticity and beauty. By supporting these artisans, we not only bring a touch of Moroccan heritage to your home but also help sustain the local community and preserve this ancient craft.

Our collection of Zellige tiles is available in a wide range of vibrant colours and intricate patterns, perfect for adding a unique and elegant touch to any space. If you have specific colour preferences not showcased on our website, feel free to inquire—we’re happy to source them for you.